Composite Mold Tools in a Fraction of the Time

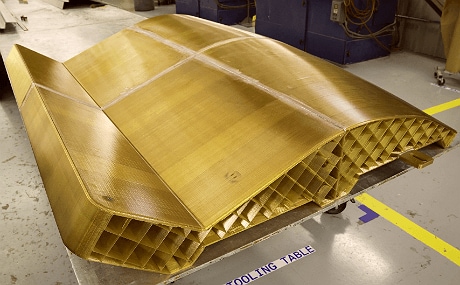

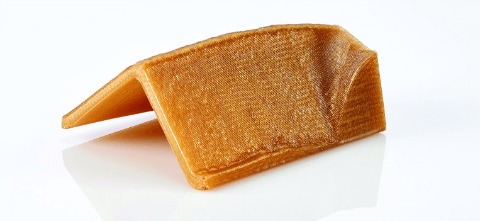

3D printed composite tooling using FDM technology offers the fastest, most cost-effective means of producing composite structures. FDM composite tools take only days to produce instead of weeks or months and avoid the high cost, touch-labor and long lead times of traditional tool fabrication.

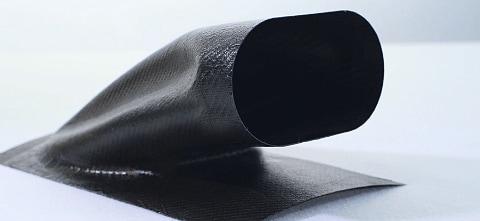

Sacrificial composite tooling simplifies the production of hollow and trapped-tool configurations, providing greater design freedom without the need for complex tooling. The tool material dissolves in a detergent solution, leaving only the cured composite part, enabling one-piece, seamless designs.

Learn More