Thule

Thule can speed new designs to market thanks to the functional prototyping capabilities of FDM materials. Learn More- 2 mins

- 2 mins

Making strong and reliable end-use parts just got easier with our materials advancements. Motivated by our customers’ demands to develop and fabricate their designs quickly to achieve the strongest part performance in the most intense environments, the first time and every time.

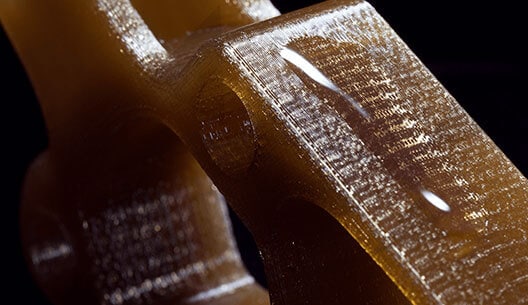

Our carbon fiber composite 3D printing material, Nylon 12 Carbon Fiber, consists of chopped fiber combined with Nylon 12 to deliver the strength and stiffness you need for rigid tools, prototypes and production parts. Its strength and stiffness make it the perfect material to replace metals like aluminum for lighter parts and tools.

Create parts with superior strength and stiffness with carbon fiber nylon 12.

With its chemical and heat resistance combined with its outgassing properties, Antero 800NA blends FDM's design freedom with the high strength and dimensional stability of PEKK - making it suitable for aircraft and space applications.

PEKK-based Antero 800NA material provides excellent chemical resistance.

The strongest of our FDM thermoplastics, ULTEM™ 1010 resin combines high tensile strength with excellent thermal properties - making it suitable for high-temperature solutions like replacing heavy composite tooling with autoclave-capable, lightweight alternatives or for withstanding heat sterilization for use in medical tooling applications.

Make composite lay-up tools much faster and lighter with ULTEM™ 1010 resin.

Its high strength-to-weight ratio and FST (flame, smoke and toxicity) rating make ULTEM™ 9085 resin a great solution for weight-reduction applications in the aerospace and automotive industries. ULTEM™ 9085 CG resin filament ships with full traceability as required by the aerospace industry.

High-strength ULTEM™ 9085 resin parts like this aircraft duct let aerospace companies reduce weight.

"I don't think everyone was aware of the possibility of being able to 3D print parts with this level of strength until they began seeing the capabilities of (carbon fiber) Nylon 12CF."

Rob Humphries, prototyping engineer, Thule

For more details, please contact your regional sales representative.

ULTEM™ is a registered trademark of SABIC or its affiliates.